As the environment becomes an ever greater concern for producers and consumers alike, the world continues to look for solutions that are truly sustainable. EVAL™ can help – providing valuable gas and chemical barrier protection in everyday life applications while reducing impact on the environment throughout the entire life cycle of the product.

EVAL™ EVOH helps conserve resources and avoid waste, reducing impact throughout the product life cycle

The benefits of EVAL™ EVOH gas barrier technology can be applied throughout the product life cycle. From farm, to shelf, to table EVAL protects quality and nutrition, offers efficiencies in transportation, and reduces waste. Food, cosmetics, and vitamins – even the fuel in your car or the safety of your home – EVAL™ EVOH offers sustainable applications in packaging and beyond. Watch the EVAL Sustainability Video for a fun overview.

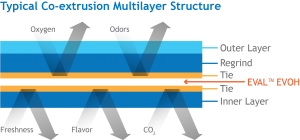

Building better barriers: 1 mm EVAL™ EVOH = 10 meters LDPE

EVAL™’s gas barrier properties give more performance per thickness than any conventional polymer, and the barrier function works in both directions.

- Value, quality, flavor and CO2 are locked inside where you want them.

- Oxygen and odors are kept outside where they belong.

Imagine a plastic wall that is 10 meters thick. Not much will get through. Now imagine that the same protective function could be realized with only 1 mm of material. With EVAL™ EVOH it can. In fact, it normally takes just a few microns of Kuraray’s EVOH copolymer to create an amazingly effective gas and aroma barrier.

Better barriers boost productivity and protect the environment

On the farm, high-barrier mulching films containing EVAL™ get things off to a good start. Keeping fumigants in the soil where they’re needed – an EVAL™ layer of just a few microns helps increase production yields. This EVAL™ barrier is so effective compared to standard films that the agricultural industry created the term TIF (totally impermeable film). Plus TIF films reduce the quantity of chemicals released into the environment and increase the amount of safely cultivable land.

EVAL™ technology allows for smart package design

After harvest, packaging using another very thin layer of EVAL™ will be enough to ensure that products get to their destination with freshness and quality intact. The quality and nutrition of the product inside a package containing EVAL™ EVOH are protected against oxygen and odor, avoiding spoilage and prolonging freshness.

Although normally associated with multi-layer plastic structures, thin multi-layer films containing EVAL™ can add functional barrier properties to almost any substrate, including renewable materials like PLA, or paper and carton. Choosing plastic makes it even easier to create exactly the right size and shape. Almost any form is possible. Our EVAL™ technicians can help you develop the optimum structure for your needs.

Safe, efficient packing, transport and distribution

Packaging containing EVAL™ can be adapted to just the right size, shape and proportion, making packing, transport and distribution as efficient as possible. It takes only tiny amounts of EVAL™ to do the job, so it’s easy to design packaging that uses fewer resources and weighs much less, without losing its protective function. In other words, lighter weight and smarter designed packaging means fewer trucks on the road for the same amount of value.

Packaging containing EVAL™ can be adapted to just the right size, shape and proportion, making packing, transport and distribution as efficient as possible. It takes only tiny amounts of EVAL™ to do the job, so it’s easy to design packaging that uses fewer resources and weighs much less, without losing its protective function. In other words, lighter weight and smarter designed packaging means fewer trucks on the road for the same amount of value.

Moreover, during transport EVAL™’s outstanding barrier properties protect products against outside odors and contamination. They remain fresh, and the resources that have been invested are not wasted. Every step of the way, the product’s quality and value is protected.

Functional packaging optimized for the shelf reduces waste

Optimized shapes fit perfectly on the display shelves. For some products, using EVAL™ means it is no longer necessary to use refrigeration, saving energy. Even better, thanks to EVAL™, product freshness is maintained without the need for artificial additives and preservatives. Plus, food can be safely stored and displayed for longer periods of time.

Optimized shapes fit perfectly on the display shelves. For some products, using EVAL™ means it is no longer necessary to use refrigeration, saving energy. Even better, thanks to EVAL™, product freshness is maintained without the need for artificial additives and preservatives. Plus, food can be safely stored and displayed for longer periods of time.

Packaging is all about getting the product to the customer, fresh and intact. In the developing world up to 50% or more of food is wasted before it can even be consumed. Even in the developed world, up to 30% of the food we buy is thrown away along with all of the many resources invested in producing it. Using functional packaging in the correct portion size is a great way to reduce waste and save those resources.

In your home and in your car

You may not know it, but it’s very likely there’s a layer of EVAL™ hard at work in your car’s plastic fuel tank. The lighter weight of the fuel system helps make your car more fuel efficient with less environmental impact from fuel emissions permeating out into the atmosphere.

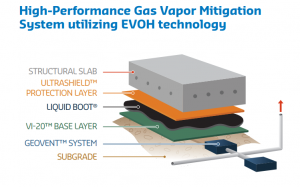

Even in your home, EVAL™ may be hard at work, helping to keep your living environment safe and efficient. Barrier liners below the foundation help keep harmful radon gas from penetrating inside and EVAL™ used in district heating pipes helps them to remain energy efficient and prolongs their lifetime. Even in your fridge, high-tech insulation panels containing EVAL™ keep your fridge and freezer energy-efficient way.

EVAL™ EVOH: barrier packaging for a circular economy

Eventually, the life of the packaging comes to an end, but even at end of life plastic packaging containing EVAL™ can be broken up and used in regrind material. In fact, many rigid bottles, cups and automotive applications already contain a layer of the recycled EVAL™ structure, in addition to the new EVAL™ functional barrier layer. When collected and sorted for recycling, structures containing EVAL™ will not disrupt polyolefine or PET recycling[PG1] streams. Avoiding waste is the best way to reduce environmental impact.

If not used for recycling, EVAL™ still has energy and function left. The energy stored in EVAL™ and the rest of the packaging can be captured from inceneration. It can be used as an alternative energy source to generate electricity[PG2] . That functional but very thin layer of EVAL™ will emit only very small amounts of CO2 and water vapor. Read more about recyclability and EVAL here.

EVAL ™ EVOH barrier technology helps to reduce impact on the environment by adding functional value

We’ve seen how EVAL™ can add real function at all stages of a product’s life cycle. From field to fridge to fork, EVAL™ helps reduce the amount of resources used, uses energy more efficiently and makes sure the product gets to you with all its flavor, vitamins, and value intact. All this efficiency means less impact on the environment, but also means more cost savings for you.

- EVAL™ allows for lighter weight packaging without losing functionality.

- EVAL™ maintains freshness and prolongs shelf life.

- EVAL™ allows packaging that is safe, reliable and convenient even while making it more effective.

- EVAL™ protects quality, and helps assure that value arrives intact.

- EVAL™ is recyclable and recoverable.

- EVAL™ helps conserve resources and avoid waste, reducing impact throughout the product life cycle.

Specifications

- Easy to process

- UV resistant

- Flex crack resistant

- Barrier to oxygen and other gases

- Barrier to aroma permeation

- Outstanding gas and aroma barrier properties (1 mm EVAL = 10,000 mm LDPE)

- Protects value and helps reduce waste

- Resistant to chemicals, oils, and fuel vapor

- Safe in use, recyclable, and recoverable

- Meets FDA and USDA requirements for use with meat and poultry products

Click on the grade below to download the datasheet (PDF-file).

Datasheet EVAL grades

- EVAL™ L171B

- EVAL™ F101A

- EVAL™ F101B

- EVAL™ F171B

- EVAL™ F104B

- EVAL™ FP101B

- EVAL™ FP104B

- EVAL™ T101B

- EVAL™ J102B

- EVAL™ C109B

- EVAL™ H171B

- EVAL™ E171B

- EVAL™ E105B

- EVAL™ G156B

Datasheet EVAL SP grades